In the industrial sector, the protection, organization, and transportation of tools, equipment, and components is essential to ensure operational efficiency and safety. Among the most effective solutions for this are flight cases, along with foam cases and molds. These products are not only essential for protecting sensitive equipment, but also help organize and optimize space, ensuring items arrive at their destination in perfect condition.

What are flight cases, briefcases, and foam molds?

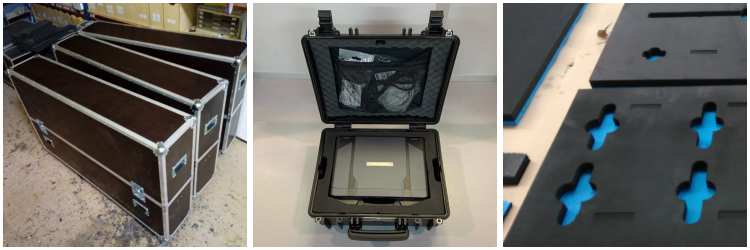

Flight casesOriginally designed for transporting sensitive equipment in the audiovisual industry, these are rigid cases or containers made of high-strength materials such as plywood, reinforced plastic, or aluminum. Their main characteristics are their robustness and ability to withstand impacts, moisture, and other environmental factors.

Briefcases: Similar to the flight casesBriefcases, although generally smaller in size, are more practical for transporting small tools and equipment. They are made of high-strength plastics or lightweight metal alloys and often include security locks and internal compartments for better organization.

Foam molds: Foam molds are used within the flight cases and carrying cases to provide an extra layer of protection for the most delicate equipment. They're made of high-density foam, often custom-cut, which offers a precise fit and cushions impacts during transport.

Applications in the Industrial Sector

1. Protection of sensitive equipment

The industrial sector involves the use of expensive and delicate machinery and electronic equipment, such as measuring instruments, sensors, industrial cameras, diagnostic equipment, among others. These elements can be vulnerable to shocks, falls, and adverse environmental conditions. The use of flight cases and briefcases provide a critical layer of protection during transport or storage, minimizing the risk of damage.

2. Optimizing storage and organization

Efficient tool and equipment management is essential to reducing downtime. Tool cases and flight cases Foam inserts allow for meticulous organization of items, preventing equipment from becoming disorganized or damaged. Custom-cut foam inserts ensure each tool or component has its own dedicated space, facilitating quick and organized access.

3. Facilitate safe transportation

For companies that operate in multiple locations or need to ship equipment long distances, flight cases They offer an ideal solution for the safe transport of tools and machinery. Thanks to their robust construction and customizable foam, equipment can travel safely without exposure to risks such as moisture, dust, or mechanical damage caused by sudden movements.

4. Reduction of costs and repair time

Damage to industrial equipment not only involves repair costs, but also lost productivity due to downtime. By using briefcases and flight cases With protective foam, businesses can significantly reduce the risk of damage during shipping and storage, resulting in lower long-term expenses and increased operational efficiency.

Why do you need a flight case in the industrial sector?

The flight cases and cases are designed to withstand extreme conditions, making them a long-term investment. With the ability to organize and secure equipment, transport time and effort are significantly reduced.

High-density foam provides excellent shock absorption, protecting even the most delicate equipment. Custom cut solutions allow for customizing the interior of briefcases and flight cases to the specific needs of each tool or piece of equipment. Minimizing the risk of damage reduces unforeseen expenses and the need for costly repairs.

In short, the use of technical packaging and foam molds has established itself as a fundamental tool in the industry to ensure the protection, organization, and efficient transportation of sensitive equipment. These products not only extend the equipment's lifespan, but also optimize logistics processes, reduce costs, and improve overall safety in industrial environments. Investing in appropriate protection solutions is undoubtedly a smart strategy for any company looking to maximize productivity and minimize risks.

You can find examples of projects we have carried out for the industrial sector here.

Thank you so much for reading and see you in the next post!