A while ago he contacted us The Rocca, a company that designs, manufactures and distributes coffee machines for both professional and home use, requesting our services to work on a foam packaging for the protection of your products.

Each client's needs are unique, so these solutions must also be unique and tailored.

Custom foam packaging – Design and manufacturing

The first part of the project was understanding the project. What did the client need? What elements needed to be taken into account?

As we already mentioned in the introduction, the project consisted of design and manufacture foam packaging personalized to protect your coffee machines from possible bumps during transport.

Based on this premise, several aspects were taken into account: the dimensions and weight of the machine, its most vulnerable and delicate areas, the method by which it would be transported, among others.

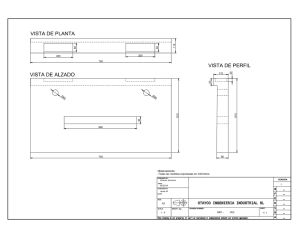

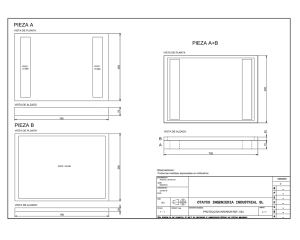

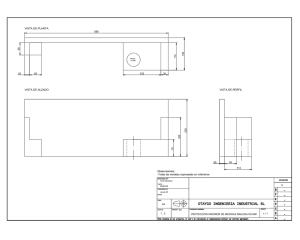

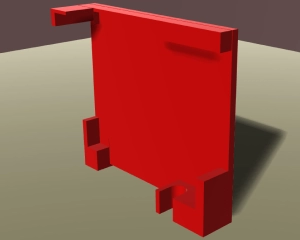

With all this, we developed a series of proposals such as these:

It is normal during this phase for some proposals to be discarded or revised several times.

One of these cases was this proposal in Stratocell (a type of ecological foam like the ones we discussed in This publication), ruled out due to the limited overall protection, as there were still delicate parts that were exposed to possible impacts.

But every discarded design is one step closer to the solution.

After investigating several solutions and discarding others, this design was chosen, which was intended to be manufactured in EPS (Expanded Polyethylene, also known as white cork or porexpan).

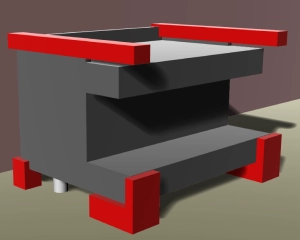

Once the design was approved, all that was left was to manufacture the part and run a test with the actual machine to ensure everything fit together perfectly.

It was a real pleasure for us to work for La Rocca. You can see the final result here!

Thank you so much for reading and see you in the next post!